Multi-drive Systems

We convert your motor list to up to date designed liquid or air cooled common DC frequency converter system with active front end solutions for industry and marine application, using advanced Eplan (electrical) and Solid Edge (mechanical 3D design) engineering with fast marine class certification and full load testing with 4.3MVA equipment.

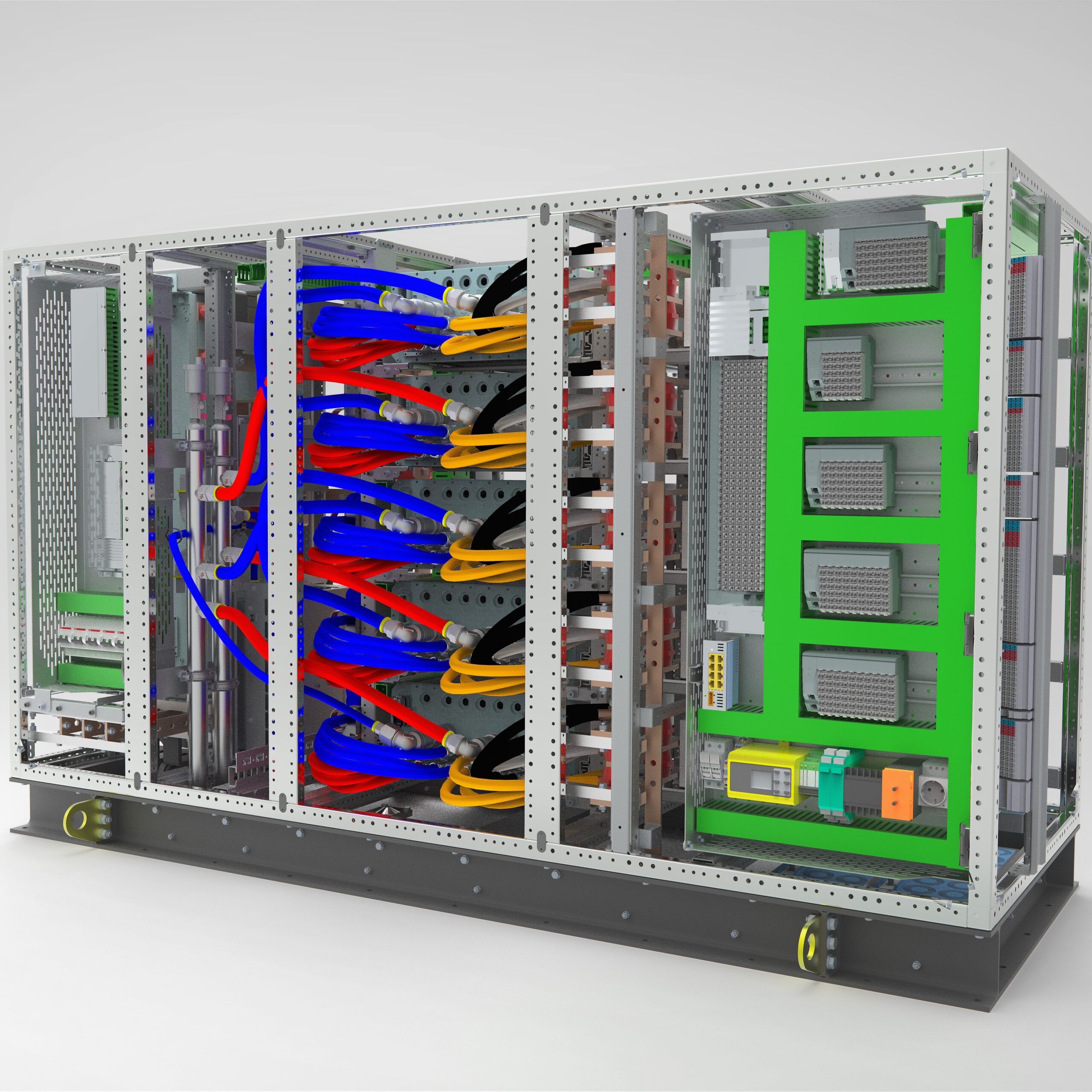

Power Distribution, MCC Systems

We convert your motor list to up to date designed power distribution and motor control switchgear (MCC) system (Sivacon S8, Logstrup, Cubic, HECON Evo, Rittal) for industry and marine application, using advanced Eplan (electrical) and Solid Edge (mechanical 3D design) engineering with fast marine class certification and full load testing.

Prototyping

We provide End-to-End prototyping solution as Engineer-To-Order (ETO) service including tailored made electrical & mechanical engineering using Eplan and Solid Edge, in-house production of mechanical parts, seamless assembly and full-load testing up to 400-780V@4.3MVA of multi-drive systems, switchboards, and power distribution.

Why choose us?

faster lead times

are expecting.

reliability

top quality

customer commitment

You can expect from HARJU ELEKTER UAB

Engineer-To-Order

It is PROTOTYPING! In the Engineer-To-Order (ETO) environment we produce customer-specific products that often require unique engineering or design work, or significant customisation activities. Typically, a huge variety of parts must be managed and delivered by a number of third parties. As ETO products are well-tailored, they are often built from difficult-to-source parts, expensive parts and highly engineered components. Acquiring the necessary components can be both a time-consuming and costly endeavour causing issues before and during production runs.

Make-To-Order

Working in the Make-To-Order (MTO) environment our consumers purchase products that are customized to their specifications. We start manufacturing the end-product as soon as the customer places the order. Some of the required components are stocked; whereas more expensive or highly customized parts may need to be produced. Although this can create an additional wait time for the consumer to receive the product, it allows for more flexible customization when compared to purchasing the product from retailers’ shelves.

Assemble-To-Order

When building an Assemble-To-Order (ATO) product we use some sub-assemblies already built, stocked and ready-to-assemble based on the customers’ requirements. Once an order is received, final assembly begins and the product is delivered with the appropriate specifications. A key advantage to an ATO approach is that minimal inventory is required so the final product can be delivered quickly.